Flanged Butterfly Valve

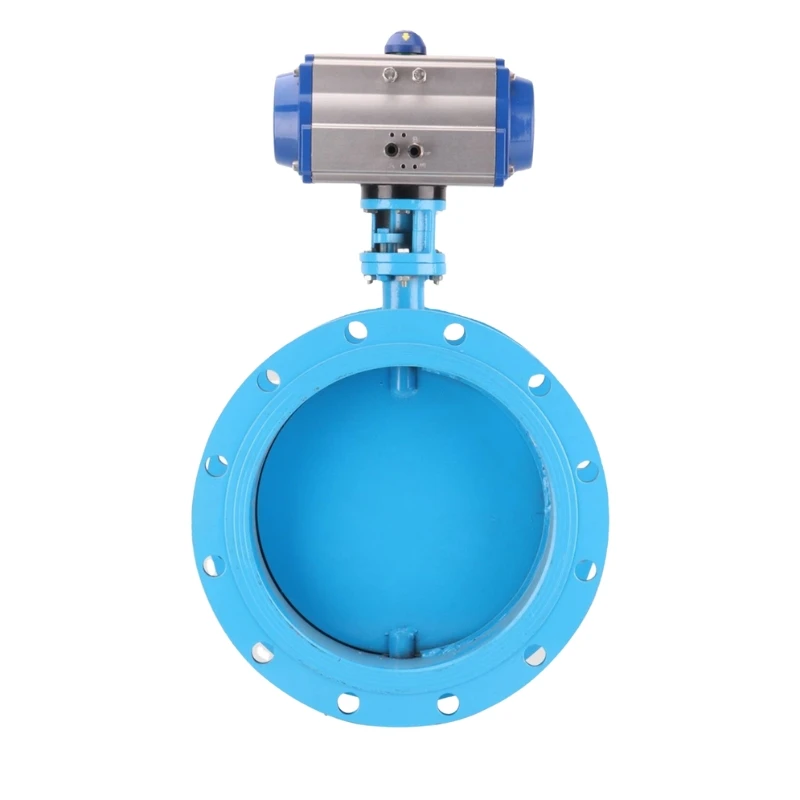

Pneumatic Actuated Flanged Butterfly Valve

Pneumatic Flange butterfly valve is a valve commonly used in industrial applications to

Understanding the Flanged Butterfly Valve: A Key Component in Valve Automation

In the realm of valve automation, the flanged butterfly valve stands out as a pivotal component, aligning seamlessly with Hearken Actuators and Controls' dedication to offering top-tier solutions in this sector. As an ISO 9001 certified company, our focus has always been on understanding customer needs and offering products that meet rigorous standards, including SIL 3, ATEX, CE Certification, and IP68 weatherproof ratings.

What is a Flanged Butterfly Valve?

A flanged butterfly valve is a type of flow control device known for its compact design and efficiency. It operates by rotating a disc to allow, restrict, or stop fluid flow. This valve type is distinct for its flanged ends, which facilitate a secure connection to pipelines, ensuring stability and a leak-proof system.

Difference Between a Wafer and a Flanged Butterfly Valve

While both wafer and flanged butterfly valves serve to control flow, their key difference lies in their design for pipeline integration. A wafer butterfly valve is designed for placement between two flanges, and is held in place by bolts that encompass the valve. In contrast, a flanged butterfly valve comes with its own set of flanges, offering a more robust connection and better suitability for larger, high-pressure applications.

Main Features of a Flanged Valve

Flanged butterfly valves, like those provided by Hearken, are known for:

- Durability: Withstanding harsh environments, aligned with our commitment to quality and certifications like Explosion-proof and Weatherproof.

- Ease of Installation and Maintenance: Simplifying processes in valve automation.

- Versatility: Suitable for various mediums, including liquids, gases, and semi-solids.

Three Types of Butterfly Valves

- Concentric Butterfly Valves: Featuring a central disc and a resilient rubber seat, ideal for lower pressure and temperature applications.

- Double-Offset Butterfly Valves: Designed for higher pressure and temperature tolerances, with a two-stage offset design.

- Triple-Offset Butterfly Valves: The most robust design, suitable for extreme conditions, employing a triple offset to minimize seat wear and enhance longevity.

Field of Use and Range

Flanged butterfly valves are versatile and find applications in various industries such as water and wastewater treatment, HVAC, oil and gas, and chemical processing. The range of Hearken's flanged butterfly valves accommodates a wide spectrum of pressures and temperatures, ensuring optimal performance across diverse settings.