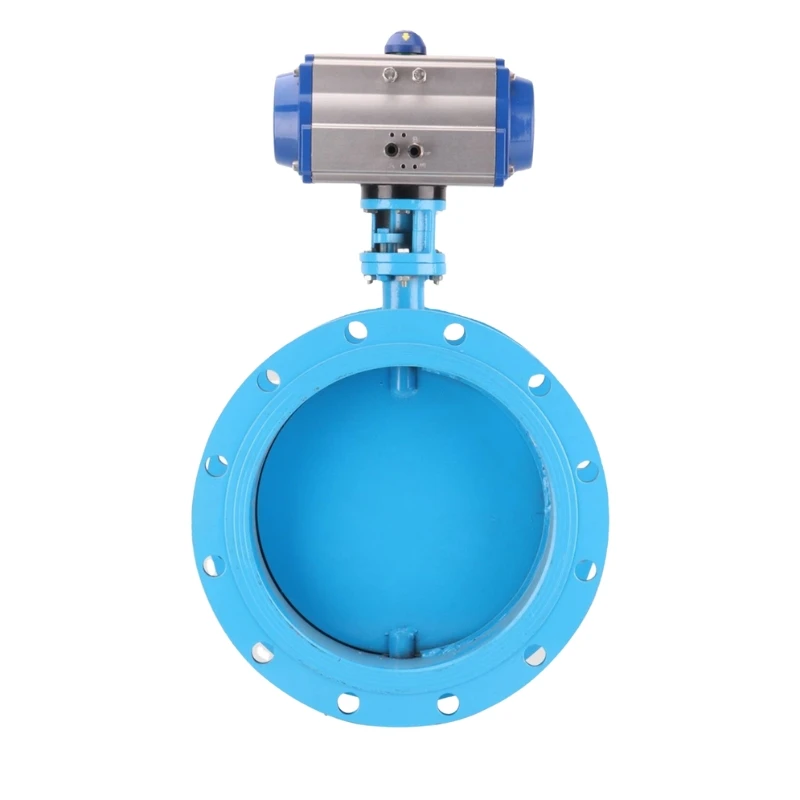

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Flanged Butterfly Valve

Pneumatic Flange butterfly valve is a valve commonly used in industrial applications to

Sanitary Pneumatic Butterfly Valve

HEARKEN pneumatic sanitary butterfly valve, default GB standard, ANSI, JIS, DIN or API 6

Stainless Steel Butterfly Valve With Pneumatic Actuator

Stainless steel pneumatic butterfly valve, small and light, easy to disassemble and main

What is an Actuated Butterfly Valve?

For the uninitiated, an air actuated butterfly valve is a type of valve that uses compressed air to control the flow of liquids or gases in a pipeline. The valve's primary component is a disc or "butterfly" that rotates on a hinge to open or close the flow path.

They're named "wafer" not because they're deliciously thin and crispy (though they are slim in design), but because they fit snugly between two pipe flanges without the need for additional fasteners. This design makes them compact and ideal for tight spaces where a robust seal is required.

Butterfly Valve Standard Features

- Space-Efficient: Due to their compact design, they're the go-to choice for industries where space is at a premium.

- Cost-Effective: Without the need for bolts or nuts, installation costs are lower.

- Quick Installation: The design lends itself to quicker setups, which is music to the ears of those who value time.

- Low Maintenance: Their simplicity translates to fewer components that could fail, leading to reduced downtime.

Uses of Air Actuated Butterfly Valves

- Water Treatment Plants: These valves are employed to control the flow of water, ensuring that treatment processes operate optimally.

- Chemical Processing: With the capability to handle various chemicals, they're used in chemical plants for processes like mixing, distribution, and storage.

- Food & Beverage Industry: In both processing and packaging stages, these valves ensure the smooth flow of liquids, minimizing contamination risks.

- Cooling Systems: Used in large cooling systems and HVAC units, they efficiently regulate the flow of coolants.

- Oil & Gas Industry: Deployed in both upstream and downstream processes, they handle crude, refined products, and gases.

- Irrigation: In agricultural setups, they're utilized to manage water distribution efficiently.

- Pneumatic Systems: As part of larger pneumatic control systems, they regulate air or gas flow in various industries.

- Fire Protection Systems: Butterfly valves are used in sprinkler systems for quick shut-off in emergencies.

Advantages of Air Actuated Butterfly Valves

- Compact Design: Unlike some other valve types, butterfly valves have a sleek and compact design, making them suitable for tight spaces.

- Cost-Effective: Generally, they are more affordable than other valve types, both in terms of initial cost and maintenance.

- Quick Operation: The pneumatic actuation ensures rapid opening and closing, optimizing process efficiency.

- Low Maintenance: Their simple design means fewer components that might fail, leading to reduced downtime and maintenance costs.

- Versatility: Suitable for a range of temperatures and pressures, they can be employed in diverse industrial applications.

- Low Pressure Drop: When fully open, the thin profile of the butterfly disc allows for minimal resistance and pressure drop.

- High Durability: With corrosion-resistant options and sturdy designs, these valves are built to last, even in harsh environments.

- Safety: Pneumatic actuators, being intrinsically safe, don’t pose a risk of sparking, making them suitable for combustible environments.

With 12 years of experience, we've perfected the art of listening—just as our name suggests. Our products, including air actuated butterfly valves, are crafted with meticulous attention to detail, ensuring they meet the highest standards.

Pneumatic Actuator Standard Features

1. Double-Acting & Spring Return Mechanisms

Double-Acting: Air's dual-role – pushing the piston in both opening and closing directions.

Spring Return: Air governs one motion, while the spring commands the return, a beautiful ballet of push and pull.

2. Rack and Pinion Design

Harnessing ancient wisdom, the rack and pinion effortlessly convert linear piston movement into the required rotational action.

3. Position Indicators

For those who appreciate a clear signal amidst the hustle and bustle, these visual markers spell out the actuator's position: open, closed, or somewhere in between.

4. Armor Against The Elements

Constructed with corrosion-resistant materials like anodized aluminum, these actuators scoff in the face of rust.

5. End-of-Stroke Adjustments

Dial in precision with adjustable stops, ensuring your actuator's motion ends exactly where you desire.

6. Direct Mounting

Cutting out the middleman, many actuators mount directly to valves, minimizing fuss and alignment woes.

7. Safety Solenoids

For those unexpected moments, these solenoids step in, regulating air flow during power or system hiccups.

8. NAMUR Mounting Standards

A nod to universal compatibility, the NAMUR interface simplifies the attachment of glamorous accessories like solenoid valves and positioners.

9. Compact Titans

Though often unassuming in size, pneumatic actuators pack a punch, delivering robust performance even in tight quarters.

10. Seals That Guard

Shielding the internals from invasive elements, high-grade seals ensure the actuator's longevity and consistent performance.