Rotary Actuator

Heavy Duty Pneumatic Actuator

The HPA-G series shift fork actuator is built in line with the latest design solution an

HPA Rack & Pinion Pneumatic Actuator With Handwheel

Pneumatic actuator is prelubricated and tested to a min onemillion operations Actuators

HEA(A) Electric Rotary Actuators Manufacturer

HEA(A) Series is a compact industrial duty quarter turn electric actuator specifically d

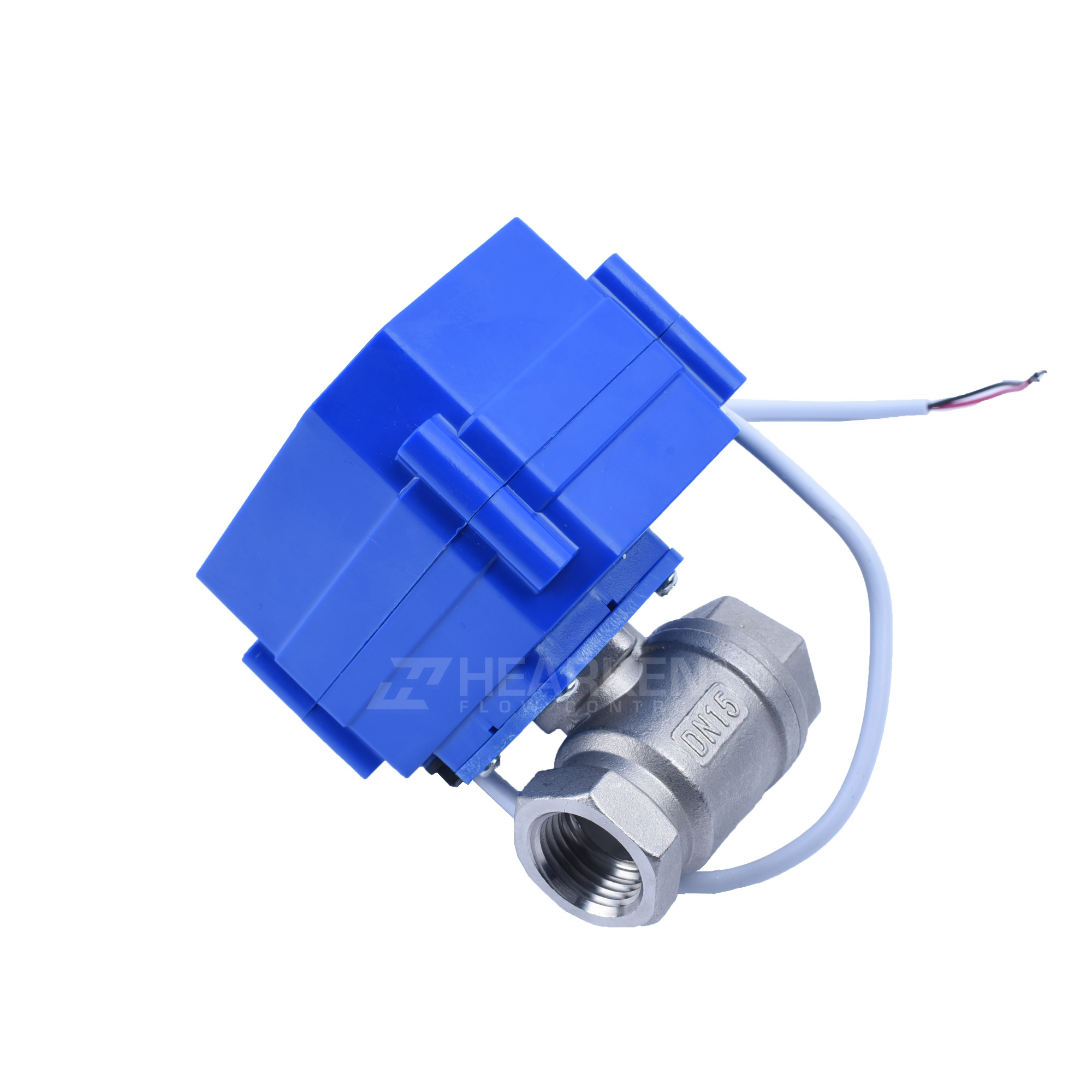

HEAS Series 2-Way Mini Motorized Ball Valve

HEAS Series 2-Way Mini Motorized Ball Valve can be used to regularly cycle to the draina

Electric Actuator Modulating 4~20mA

HEA Series Quarter-Turn Electric Actuator is used for controlling 0~270 degree Rotation

Rotary Electric Actuator

HEAS-N series quarter turn electric actuator is constructed with internal mechanical cam

Multi-Turn Electric Actuator

The multi-turn small electric valve actuator is a new product extended from the small-di

Rack and Pinion Pneumatic Actuator

The cylinder body of the pneumatic actuator is made of extruded aluminum alloy and is tr

Pneumatic Actuator with Limit Switch Box

The rack-and-pinion pneumatic actuator has the advantages of simple structure, stable an

What is electric rotary actuator?

Electric rotary actuators, harnessing electromagnetic energy from motors, spur component rotation. Offering control and indexing functions, they facilitate multiple position halts throughout strokes. Their rotational aspect may manifest as either a disc-like shaft or a platform.

Electric rotary actuators, integral in modern automation, transform electrical energy into mechanical motion—specifically, rotational movement. These actuators are particularly adept in applications demanding precision and controlled rotational actions. They are essential in valve control, robotics, and positioning systems. Electric rotary actuators consist of an electric motor coupled with a gear or belt system, facilitating exact control over rotation angle, speed, and torque. This precision makes them a versatile and efficient choice for diverse mechanical automation needs.

What are electric rotary actuators used for?

Actuators play a pivotal role in automating control valves across various process engineering systems. A rotary actuator delivers rotational force, ensuring at least one full revolution to the control valves.

What is the advantage of rotary actuator?

Prime benefits of pneumatic rotary actuators include straightforward operation, robustness, potent force delivery, and suitability for perilous settings. Conversely, hydraulic rotary actuators are often harnessed in scenarios demanding hefty torque generation.

- Precision in rotational control

- Suitability for applications requiring controlled speed and torque

- Reliable and efficient in various automation settings

Electric actuator Rotary type

An electric actuator of the rotary type is a device designed to convert electrical energy into mechanical motion, specifically rotational movement. This type of actuator is often used in various applications where precise and controlled rotational movements are required, such as in valve control, robotics, and positioning systems. The electric rotary actuator typically consists of an electric motor that drives a mechanism, such as a gear or a belt, to produce the desired rotation. This allows for accurate control of the angle, speed, and torque of the rotation, making it a versatile and efficient solution for many mechanical automation needs.

What is important to you when you buy pneumatic actuators ?

Hearken pneumatic actuators has passed with ATEX approved, CE approved, SIL approved as per international qualification standard.

Hearken rack and pinion Pneumatic actuators are designed for use in quarter turn applications and tested to the one million operations. Actuators are available double acting and spring return models. Its meet international ISO5211 standards for easy valve mounting and replacement visual position indicator will monitor the valve open and closed position. The quality of our pneumatic actuators provide long and safe performance for your valve control . we are here for your valve automation.

- Movement : Standard adjustable 90°±%

- Body:Hard anodized extruded aluminium alloy and stainless steel

- Actuator Types: Double acting pneumatic actuators and Spring return (Single acting) Pneumatic actuator

- Valve Options: Pneumatic actuator ball valve , Pneumatic actuator butterfly valve, Pneumatic angle seat valve, Pneumatic gate valve or Pneumatic globe valve

- Actuator Options: AT series rack and pinion pneumatic actuators, Scotch yoke pneumatic actuators , Linear pneumatic actuator and Hydraulic pneumatic actuators.

- Springs:High tensile spring sets of alloy steel

- Piston Shaft:Nickel plated alloy steel reduces friction

- End Caps:Polyester coated die cast aluminium

- Optional accessories: Solenoid valves, Limit switch box, Valve positioner or Air filter regulator

- Advantage: our pneumatic actuators products are not only price competitive but also perform as well as or better than more expensive products.

- Quality: our each pneumatic actuator is tested on the test bench.

- Additional: if your have any requirements about our pneumatic actuators,please welcome to write mail to us @ [email protected] for getting more information and service from us.

Key Applications of Electric Rotary Actuators

Rotary actuators, both pneumatic and electric, are used in various industrial applications such as:

- Control Valves in Process Engineering Systems

- Robotics for precise movement control

- Positioning Systems in various industrial applications

Single Acting VS Double Acting Actuators

Single Acting Rotary Pneumatic Actuator

Single acting actuators, often termed as 'spring-return' actuators, utilize air pressure to move the actuator in one direction and a spring to return it to the original position. These actuators are efficient for simple on/off operations where the actuator needs to return to a safe position in case of power or air supply failure. They are typically smaller and more cost-effective but provide less force compared to double acting actuators.

Double Acting Rotary Pneumatic Actuator

In contrast, double acting actuators use air pressure to open and close the valve. This design offers more control and efficiency in operations where precise regulation of the valve position is required. Double acting actuators are essential for modulating control and situations where air pressure may not always be reliable to return the actuator to its original position.

Design of Rotary Pneumatic Actuators

Rack-and-Pinion Design

Rack-and-pinion actuators are known for their compact design and high efficiency. They convert linear motion of a piston into rotational motion using a gearwheel (pinion) and a rack. This design is suitable for both single and double acting actuators and is widely used due to its simplicity, reliability, and ease of maintenance.

Scotch Yoke Design

Scotch yoke actuators transform linear motion into rotational motion using a slotted yoke and a sliding piston. This design is particularly effective for producing high torque at both ends of the actuator’s stroke, making it ideal for heavy-duty applications.

Vane-type Design

Vane-type actuators consist of a slotted rotor with extending vanes, placed inside a cylindrical housing. They are known for their smooth operation and are commonly used in applications requiring precise control.

Selection of Rotary Actuators

When selecting a rotary actuator, consider the following factors:

- Type of Actuator: Choose between pneumatic and electric based on power source availability, control requirements, and environmental considerations.

- Torque Requirements: Ensure the actuator provides sufficient torque for the application.

- Control Precision: Electric rotary actuators offer precise control, while pneumatic versions are better for simpler on/off control.

- Environment: Consider factors like temperature, humidity, and potential explosive environments, which might require specific certifications like ATEX.

- Maintenance and Durability: Assess the ease of maintenance and the durability of the actuator in the given industrial environment.

At Hearken, our pneumatic rotary actuators, embodying the pinnacle of efficiency and reliability, have garnered ATEX, CE, and SIL certifications, aligning with international standards. Our rack and pinion pneumatic actuators, designed for quarter-turn applications, have been rigorously tested to endure over a million operations.